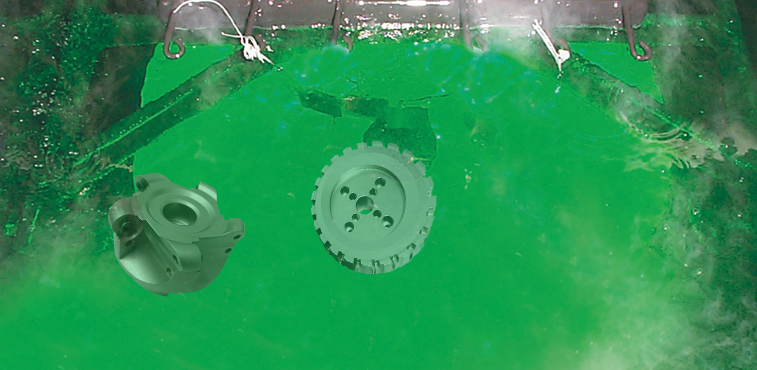

Electro Plating Products is applauded for the following features:

The Electrical Counterpart to EN plating - is primarily used for the deposition of a layer of

metal in order to provide the material being plated with a desirable property such as

abrasion and corrosion protection, lubricity or aesthetic qualities that it would not

otherwise have. Electroplating is also used to build up the thickness of undersized parts.

Electroless nickel plates are used to achieve some of the same goals as electroplating.

However, EN plating offers several advantages over its electrolytic nickel.

We are provides top-quality Glass Beading services for various

industrial applications. This process uses fine glass beads at high pressure to clean,

polish, and finish surfaces, removing rust, paint, and contaminants while preserving

material integrity.

Our services enhance durability, appearance, and performance, making them ideal for

industries like automotive, aerospace, and manufacturing. With a focus on precision and

quality, we deliver reliable solutions tailored to your needs.